August 15.2025

In the construction industry, even the smallest miscalculation can snowball into massive budget overruns, missed deadlines, and costly disputes. Quantity takeoff, the process of calculating the materials, components, and labor needed for a project, is the foundation of accurate cost estimation and efficient resource planning.

In Asia’s fast-paced construction markets, where projects range from megacities in China to high-rise hubs in Singapore, the pressure to deliver on time and on budget is intense. With competition growing fiercer and project timelines shrinking, the shift from manual to digital, BIM-based quantity takeoff is gaining momentum. This isn’t just about adopting new tools; it’s about gaining a lasting competitive edge.

What Is Quantity Takeoff?

Quantity takeoff (QTO) involves identifying, measuring, and listing all materials and resources required to complete a construction project. These figures are then used to prepare detailed cost estimates, develop bids, and plan procurement.

While it’s closely tied to cost estimation, they are not the same:

- Quantity takeoff determines how much material or labor is needed.

- Cost estimation applies prices to these quantities to calculate the overall project cost.

Without precise takeoff data, cost estimates become guesswork, a risk no contractor can afford in today’s competitive landscape.

Types of Quantity Takeoff Methods

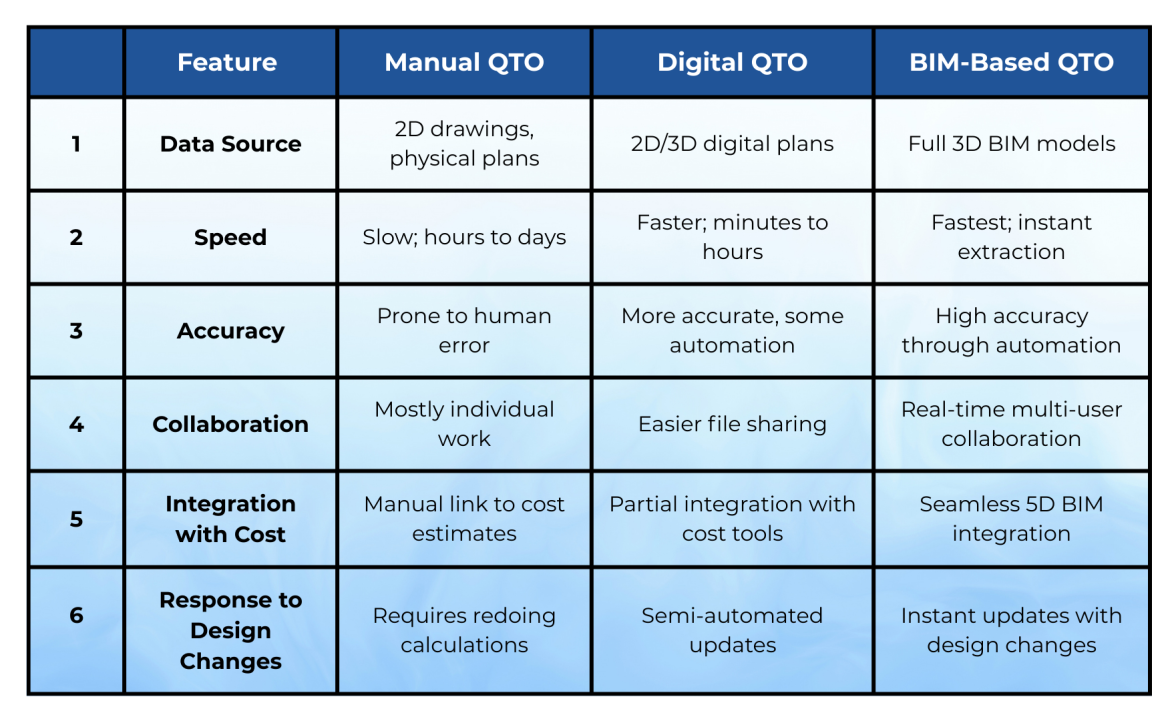

In today’s construction industry, quantity takeoff can be performed in three main ways: the traditional manual method, the modern digital approach, and the advanced BIM-based method.

Many companies start with manual QTO for its low upfront costs, especially on small-scale projects. But as project complexity increases, so does the need for greater speed and accuracy, driving a transition to digital and, eventually, BIM-based solutions. This progression isn’t just about technology adoption; it’s about staying competitive as client expectations rise and timelines tighten.

Manual Quantity Takeoff: The Traditional Approach

For decades, manual quantity takeoff was the industry standard. Estimators would spread out paper drawings, use scale rulers to measure lengths and areas, and manually record figures into spreadsheets.

While this method still has a place in smaller projects or regions with low digital adoption, it is fraught with challenges:

- Time-consuming

Measuring and recording data by hand takes days or even weeks. - Error-Prone

One misread scale or misplaced decimal can derail a budget. - Rigid

Updating quantities after design changes means redoing work from scratch.

As projects grow in scale and complexity, the drawbacks of manual QTO become too significant to ignore.

Digital Quantity Takeoff: The Modern Upgrade

Digital quantity takeoff tools streamline the process by allowing measurements to be taken directly from CAD drawings or PDF plans. Instead of physically tracing each element, estimators can click on a drawing, automatically calculate dimensions, and generate reports in minutes.

Advantages include:

- Faster Turnaround

Estimates can be produced days earlier than with manual methods. - Greater accuracy

Consistent measurements across the team. - Improved Collaboration

Results are easily shared via cloud platforms, keeping all stakeholders aligned.

While digital QTO solves many manual inefficiencies, it’s still limited if designs change frequently, which is where BIM comes in.

BIM-Based Quantity Takeoff: The Next Level

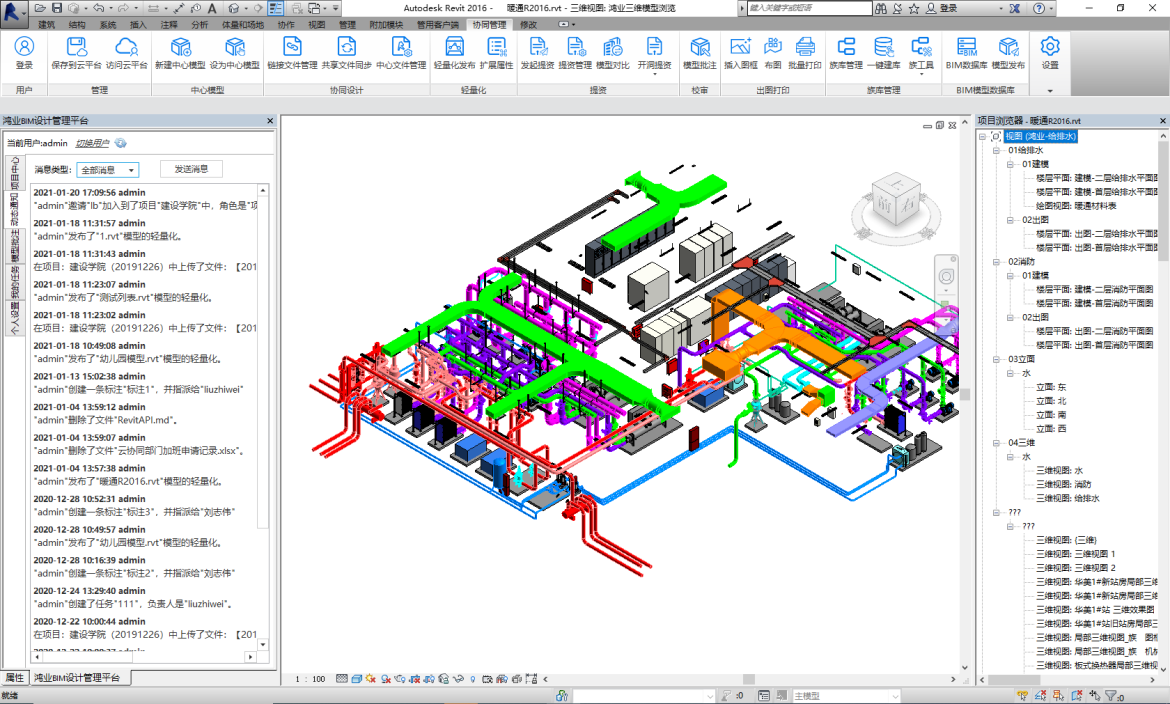

Building Information Modeling (BIM) takes digital quantity takeoff beyond simple measurement, transforming it from a static, reactive task into a dynamic, model-driven process.

In BIM-based quantity takeoff, quantities are automatically generated from the 3D model itself, not manually calculated or traced. This ensures every dimension, component, and material is accounted for, even as designs evolve.

Key benefits include:

- Automated Extraction

The system detects and counts every modeled element, from structural beams to MEP fittings, with no manual re-measurement. - Real-Time Updates

Any design change in the BIM model updates the takeoff instantly, reducing the risk of outdated estimates. - 5D BIM Integration

Links quantities with cost and schedule data, enabling more accurate budgeting, forecasting, and project planning. - Improved Collaboration

Designers, quantity surveyors, and contractors work from a single, coordinated data source, minimizing discrepancies. - Regional Compliance

Leading BIM-based tools, such as Glodon Cubicost, can align automatically with local measurement standards in Asia, ensuring both speed and accuracy.

By shifting to BIM-based QTO, construction teams gain a faster, more transparent, and more reliable foundation for bidding and cost control, a critical advantage in Asia’s competitive project environment.

Manual vs Digital vs BIM-Based Quantity Takeoff

Environmental and Sustainability Gains

BIM-based quantity takeoff isn’t just about speed and accuracy, it also supports sustainable construction practices:

- Reduced Material Waste

More precise estimates mean fewer surplus materials. - Optimized Procurement

Just-in-time ordering reduces storage needs and spoilage. - Sustainability Tracking

Quantities can be linked to environmental impact metrics.

In a region increasingly focused on green building certifications, these benefits are becoming a competitive advantage.

How to Transition from Manual to Digital (and Beyond)

Moving from manual methods to BIM-based digital quantity takeoff is more than a software upgrade, it’s a strategic transformation in how your team works. Success depends on thoughtful planning and effective change management:

- Evaluate Current Workflows

Map out your existing QTO process and identify bottlenecks such as repeated measurements, slow updates after design changes, or errors in manual data entry. - Upskill Your Team

Invest in BIM training for estimators, quantity surveyors, and project managers to ensure everyone can work confidently with model-based data. - Start with Pilot Projects

Test your digital process on smaller, low-risk projects to refine workflows and build internal confidence before a full-scale rollout.

- Select the Right Software

Choose a quantity takeoff tool that supports local measurement standards, integrates seamlessly with your BIM environment, and scales to your project types.

Future Trends in Quantity Takeoff

The next decade will bring even more transformative changes to quantity takeoff:

AI-Assisted Takeoff

Artificial intelligence will further reduce the need for manual intervention by learning from historical data and identifying measurement patterns automatically. This means estimators can focus on higher-value decision-making instead of repetitive tasks.

AR/VR Integration

Augmented and virtual reality will allow on-site teams to visualize takeoff data in real time, overlaying material quantities onto the physical site through wearable devices or headsets. This could drastically improve communication between the office and field teams.

Generative Design Links

Future QTO tools will integrate with generative design software, automatically producing design alternatives that optimize material use, cost efficiency, and sustainability, before a single line is drawn on the final plans.

Conclusion: The Future Is Automated

From rulers and calculators to fully automated, model-based workflows, quantity takeoff has evolved into a high-tech discipline. In Asia’s competitive construction sector, adopting BIM-based quantity takeoff is no longer optional, it’s a strategic necessity for accuracy, speed, and adaptability.

Glodon Cubicost is built for Asia’s construction market, combining BIM integration, automation, and compliance with local measurement standards. It enables faster, more reliable estimates while strengthening your competitive edge.

If you’re ready to streamline your quantity takeoff process and win projects with greater confidence, reach out our team today to see Glodon Cubicost in action.