December 05.2025

Project Marmot, Google’s first data centre in Malaysia, is redefining how large-scale M&E works are managed in fast-paced, high-stakes environments. Spanning approximately 100,000 m² and built to support the nation’s digital ambitions, the project demanded precise modelling, faster quantification, and seamless coordination across complex building services. To meet these challenges, WT Partnership turned to Glodon Cubicost TME, transforming previously fragmented workflows into an integrated, efficient, and highly traceable approach that supports the project throughout the post-contract stage.

About WT Partnership and Project Marmot

Figure 1. Groundbreaking Ceremony for Google’s First Data Centre in Malaysia

This data centre project, located in City of Elmina, Shah Alam, Selangor, spans approximately 100,000 m². Construction broke ground in October 2024, with completion anticipated by early 2026. WT Partnership (WT), a leading international project advisory firm, provided quantity surveying and cost management services for this groundbreaking project. Leveraging advanced BIM tools like Cubicost TME, WT ensured precise Mechanical & Electrical (M&E) modeling and quantity take-off during all project stages, contributing to the project’s efficiency and sustainability goals.

WT empower clients to grow, inspiring confidence through independent advice and inventive thinking to create sustainable value across all aspects of the built environment. They are a leading international project advisory firm with more than 75 years of multi-sector experience. Their clients can tap into the collective thinking of the people in the industry, operating from 80+ offices throughout Asia, North America, Oceania, Africa and Europe.

In Asia, WT Partnership (M) supports their clients across property, construction and infrastructure with an award-winning team of specialists in infrastructure advisory, cost management and quantity surveying, project delivery and digital portfolio management. WT provides quantity surveying and construction cost management services to almost all sectors of the built environment. Their focus is on client’s needs, and they are committed to provide a high-level service at all stages of a building project, from appraisal to post practical completion, using the extensive body of knowledge and benchmarking data that they are able to call upon.

Challenges in M&E Modelling and Quantity Take-Off

The design of data centre project presented notable hurdles in M&E systems management, forcing teams to switch between disparate tools and leading to fragmented workflows. This inefficiency was particularly acute during the rushed project stages, where manual measurements consumed excessive time and resources, increasing the risk of errors and delaying critical decision-making.

“Previously, no single software platform existed that could seamlessly integrate M&E systems and services with taking off. However, TME compiles all trades within one software, delivering a significant advantage in M&E quantity take-off.” – Muhamad Izwan, Senior Contracts Executive, WT Partnership

Compounding these issues were the complexities of coordinating multiple M&E trades such as ACMV (Air Conditioning and Mechanical Ventilation), Fire Services, Plumbing, and Electrical, within a high-stakes data centre environment. The need for rapid, accurate quantification amid tight timelines and evolving design requirements demanded a more unified approach to avoid rework and ensure compliance with stringent performance standards.

Glodon TME as Innovative Solutions for Digital Take-off Process

WT turned to Cubicost TME solution to address these challenges head-on in this project, deploying it extensively on Fire Services trade. The solution’s integrated capabilities allowed for streamlined model creation and quantification in a single environment, eliminating the silos of traditional methods.

Key Features of TME Proved Instrumental in Overcoming the Project’s Demands:

1. Device Identify

This function automatically detects and processes design elements from drawing, enabling swift conversion into quantifiable models and accelerating the initial measurement process.

2. Define Region

This function enables users to categorise and summarise the quantified quantities based on the defined project areas, offering convenience for quantity categorisation and classification.

3. 3D Modeling

By importing 2D drawings, the solution enables the team to achieve better visualization through 3D models, leading to a deeper understanding of the project design.

These tools delivered key advantages to WT's team by streamlining detection and conversion processes, enhancing categorisation efficiency, and empowering team to adapt swiftly to quantity adjustments and high efficiency demands without compromising timelines to the data centre project.

The Advantages of Using Glodon Cubicost TME

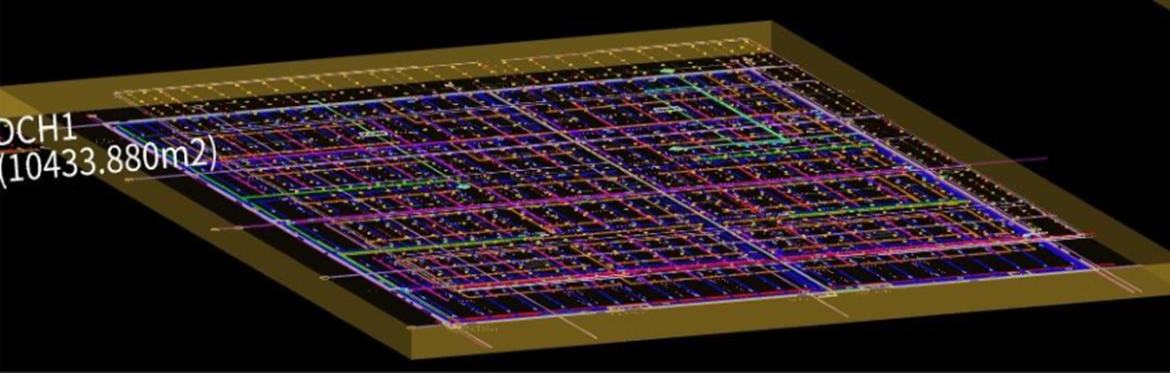

Figure 2. DCH1 Area Fire Protection System Layout Modelled Using Cubicost TME

TME has transformed WT’s workflow by enabling rapid quantity measurement, significantly enhancing efficiency. Currently, WT has deployed exclusively for the fire services trade, allowing for streamlined model creation and precise take-offs in a unified environment in the project. This approach has accelerated processes, improved accuracy, and promoted better collaboration while minimising errors that could affect the project’s sustainability and digitalisation goals.

As the project remains ongoing, the M&E team is actively modelling and quantifying elements from the other trades, including ACMV, plumbing, and electrical systems. The team intends to integrate these, along with fire services, into a single cohesive model during the final account stages, enabling holistic visualization and comprehensive quantity take-offs.

The adoption of TME has strengthened WT's ability to provide reliable value, supporting the project's role in advancing Malaysia's digital infrastructure and alignment with international benchmarks for efficiency and innovation.

Project Marmot demonstrates how Glodon Cubicost TME can transform fragmented M&E workflows into a cohesive, accurate, and efficient digital approach. With model-based clarity, faster take-offs, and improved coordination, WT Partnership has strengthened its capability to deliver high-stakes data centre projects with confidence.

Looking to enhance your M&E modelling and quantity management? Contact us to explore how Glodon Cubicost TME can support precision, efficiency, and collaboration on your next project.