December 29.2025

Managing electrical quantity take off in a large design and build retail project is never simple, especially when frequent addendums, zoning requirements, and complex layouts are involved. For the Sunway City Ipoh Mall project in Perak, Westpac Engineering faced exactly these challenges during the pre tender stage. By adopting Glodon Cubicost TME, the team was able to streamline electrical quantity take off, manage design changes more efficiently, and deliver accurate bill of quantities packages despite a demanding project environment.

About Westpac Engineering and the Sunway City Ipoh Mall Project

Sunway City Ipoh Mall is a major retail development located in Tambun, Ipoh, Perak, with an approximate built up area of 131,467 m². Delivered under a design and build framework, the project incorporates extensive electrical systems across multiple zones, including areas with double volume spaces that require careful routing and wiring diversions. The entire development is segmented into four distinct zones, each requiring its own bill of quantities package.

Westpac Engineering implemented Cubicost TME during the pre tender stage for electrical works to support quantity take off and cost preparation. With numerous drawing revisions and addendums issued throughout the pre tender phase, the team needed a solution that could adapt quickly without compromising accuracy. The project is anticipated to be completed by Q4 2027.

Challenges in Electrical Modelling and Quantity Take Off

The design and build nature of Sunway City Ipoh Mall introduced several challenges that made electrical quantity take off particularly demanding.

1. Frequent Addendums and Drawing Revisions

During the pre tender stage, continuous addendums and drawing updates required constant adjustments to quantities. Manual methods made it difficult to track changes efficiently and increased the risk of errors.

2. Double Volume Areas and Complex Routing

Certain areas of the mall featured double volume spaces, adding complexity to electrical routing and measurement. Accurate quantity take off required careful modelling to reflect these design conditions.

3. Zoning Requirements for Separate BQ Packages

The project was divided into four zones, each requiring its own bill of quantities. This demanded precise segregation of quantities to ensure clarity in pricing and reporting.

4. Wiring Diversions for Maintenance and Adaptability

The electrical design required multiple wiring diversions to support maintenance access and long term adaptability. Managing these variations increased the pressure on accuracy and efficiency during quantity take off.

Using Cubicost TME to Support Electrical Quantity Take Off

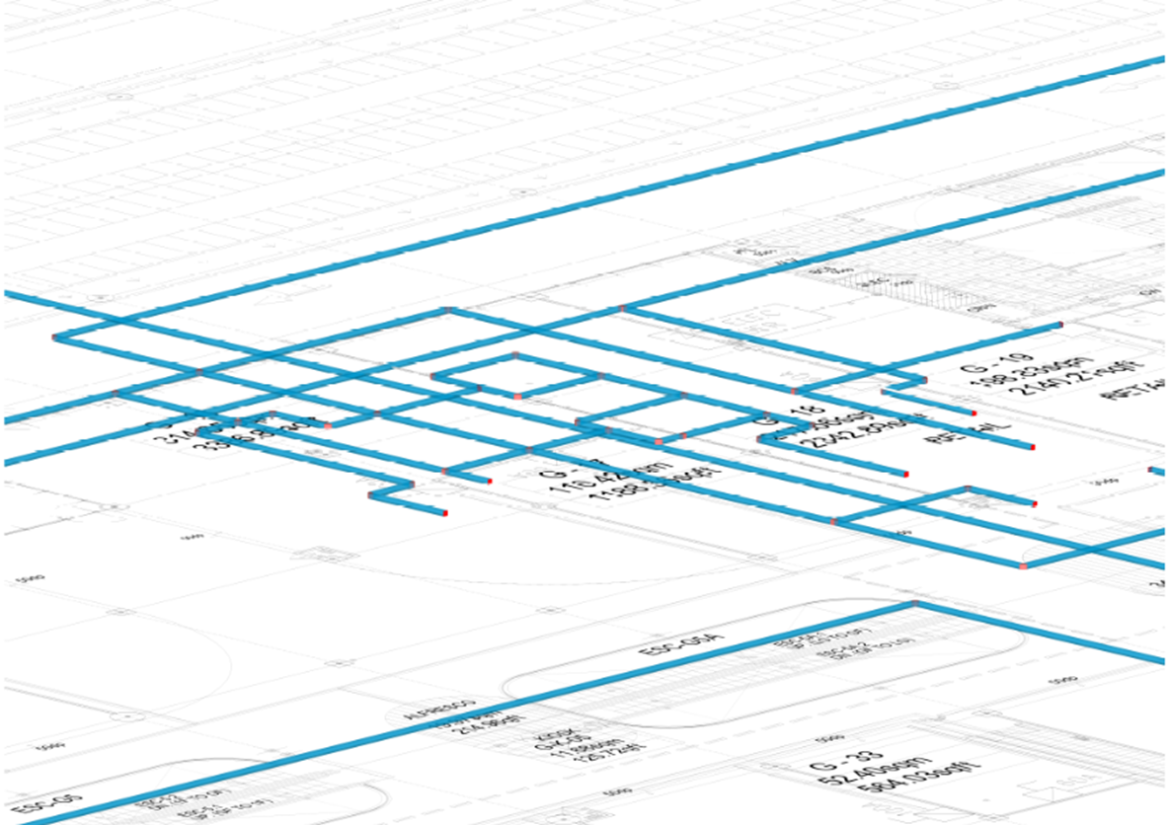

Figure 1. Cable tray system layout modelled in Cubicost TME for electrical quantity take-off

To overcome these challenges, Westpac Engineering adopted Cubicost TME for the electrical scope during the pre tender stage. The software provided fast and flexible quantity take off capabilities while allowing modelled items to be easily adjusted as designs evolved.

Key features of Cubicost TME that supported the project included:

1. Cable Tray Wiring, which allowed wires to be inserted into cable trays with defined start and end points, ensuring accurate representation of complex routing

2. Addendum, which enabled quick comparison of drawing revisions with a single click, eliminating the need for manual checks

3. Device, which automatically detected and processed design elements from drawings, speeding up the initial measurement workflow

4. Define Region, which allowed quantities to be categorised and summarised by specific project zones, supporting separate BQ packages

“Overall, TMEC is a flexible software with versatile methods for fast quantity take-off, including automatic generation of vertical trays connected to distribution boxes, intelligent adjustments to tray vertical heights based on DB elevations, and additional utilities like reserved lengths for wiring and region-based quantity separation that enhance usability and precision." — Siti Norsyafiqah, Project Cost Engineer, Westpac Engineering

These tools enabled Westpac Engineering to manage frequent changes while maintaining accuracy and consistency throughout the pre tender process.

Cubicost TME: Measurable Results and Workflow Improvements

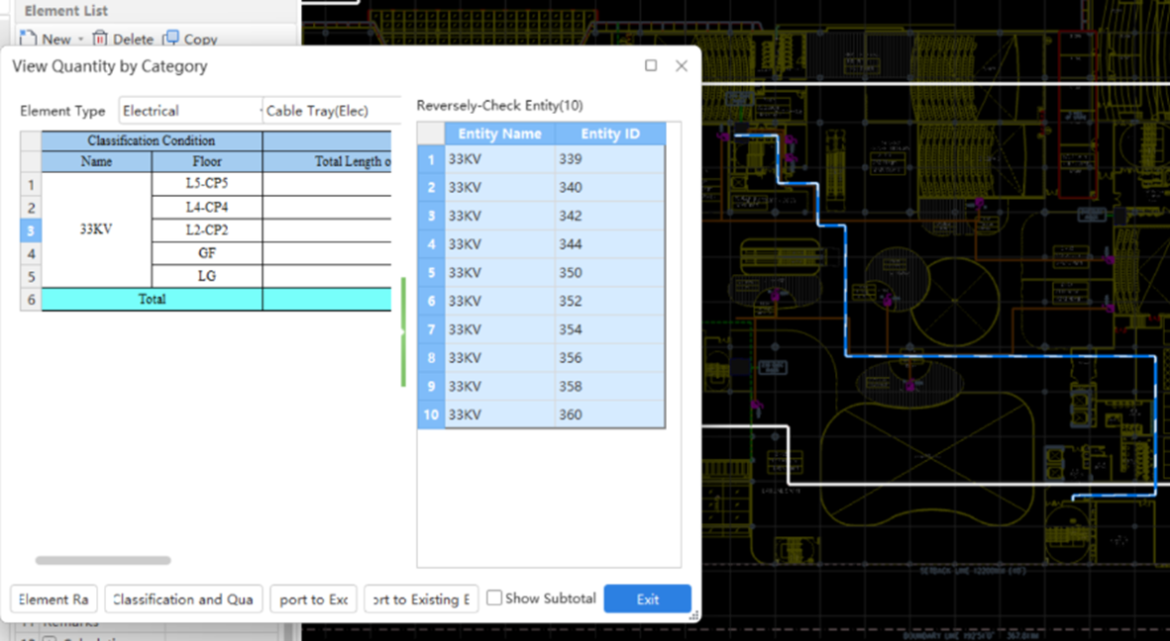

Figure 2. Reversely-check entity function in Cubicost TME for quantity traceability

The adoption of Cubicost TME delivered clear improvements in efficiency, accuracy, and coordination.

1. Faster Quantity Take Off under Design Changes

Cubicost TME allowed the team to respond quickly to addendums and drawing revisions without redoing work from scratch, significantly reducing turnaround time.

2. Accurate Segregation of Quantities by Zone

Using the Define Region function, quantities were clearly separated according to the four project zones, ensuring accurate bill of quantities packages and better pricing clarity.

3. Reduced Rework and Improved Coordination

Automated detection and modelling reduced errors typically caused by manual revisions. This minimised rework and improved coordination across teams.

4. Better Support for Maintenance Considerations

Intelligent wiring features and reserved lengths helped ensure that electrical systems were planned with maintenance and adaptability in mind, even in complex double volume areas.

Overall, Cubicost TME enabled Westpac Engineering to deliver accurate, well organised electrical quantity take off in a challenging design and build environment.

The Sunway City Ipoh Mall project demonstrates how Glodon Cubicost TME can support electrical contractors in managing complex design and build projects with confidence. By enabling rapid quantity take off, flexible handling of addendums, and clear segregation of bill of quantities, Cubicost TME helped Westpac Engineering improve efficiency, reduce errors, and maintain accuracy during a demanding pre tender stage.

If your team is facing similar challenges with frequent design changes, complex electrical layouts, or multi zone quantity breakdowns, Glodon Cubicost TME can help you achieve the same level of clarity and control. Discover how Glodon Cubicost TME can enhance your quantity take off and cost planning workflows. Contact our team today to start your digital construction journey.