August 11.2025

When it comes to delivering MEP (Mechanical, Electrical, and Plumbing) systems in large healthcare facilities, precision and speed are critical. But what happens when overlapping duct designs and confusing system layouts threaten to derail your timelines? That’s exactly the challenge faced by Sunline M&E Services Sdn Bhd during the tender phase of the Avisena Specialist Hospital project in Shah Alam. With high stakes and tight deadlines, Sunline turned to Glodon Cubicost TME—a digital solution that transformed their workflow, cut down manual errors, and set a new benchmark for digital construction in Malaysia.

About Sunline M&E and the Avisena Specialist Hospital Project

Established in 1982, Sunline M&E Services Sdn Bhd is a Malaysian leader in designing, installing, and maintaining air conditioning and mechanical ventilation systems. With a paid-up capital of RM2 million, the company is shareholder-managed, registered with key government statutory bodies, and a proud member of the Master Builders Association Malaysia (MBAM) and Malaysian Air Conditioning and Refrigeration Association (MACRA). Known for its work across healthcare, industrial, and commercial sectors, Sunline brings decades of expertise to every project.

One such project was the Avisena Specialist Hospital in Shah Alam, Selangor—a 7,500 m² state-of-the-art medical facility. During the 27-month project duration, Sunline was responsible for implementing the hospital's air conditioning and mechanical ventilation systems. However, the team encountered several technical and coordination challenges that threatened to disrupt project timelines during the tender phase.

Project Challenges: Overlapping Drawings and Productivity Setbacks

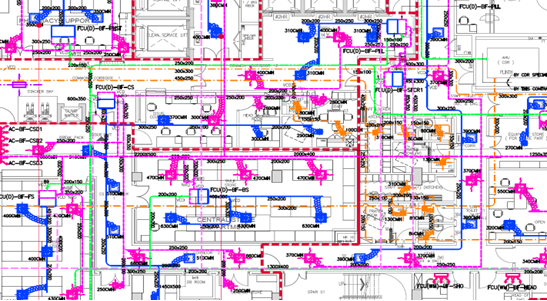

Figure 1. Plan layout of ducting works for air conditioning and mechanical ventilation systems.

1. Overlapping Ducts in 2D Drawings

Consultant-provided 2D layout drawings often used single-line representations for ducting systems. These lines frequently overlapped, making it hard to distinguish which duct belonged to which system. This ambiguity complicated the quantity take-off process, especially when performed manually.

2. Difficulties to Differentiate the System

Even with access to 3D models, the sheer scale of ducting work resulted in cluttered visuals. The complexity made it difficult for engineers to identify and differentiate between various systems, increasing the risk of misinterpretation and rework.

3. Impact on Timeline and Productivity

The combined issues of overlapping drawings and system confusion directly impacted productivity. Engineers spent excessive hours deciphering drawings, which delayed workflows and strained the overall project schedule.

The Digital Solution: Glodon Cubicost TME

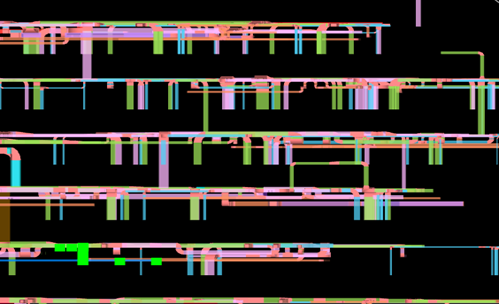

Figure 2. Vertical duct layout with riser view generated in Cubicost TME.

To overcome these inefficiencies, Sunline M&E Services adopted Glodon Cubicost TME, a next-generation quantity take-off solution tailored for MEP professionals. The software brought clarity and structure to the team’s workflow through powerful digital features:

1. Hide and Show Elements via Colour

This feature enabled the team to assign specific colours to different systems, allowing them to filter visibility and isolate components with ease. It dramatically reduced visual clutter and eliminated the need for manual sorting.

2. Layer Prioritisation

Cubicost TME also allowed Sunline to prioritise which layers or systems to model and measure first. This created a more logical task sequence and improved the structure of their 3D cost model—enhancing accuracy and efficiency.

By integrating these tools into their workflow, Sunline was able to digitally manage complex consultant drawings more intuitively, reducing both the risk of error and the time spent on manual coordination.

Results: Time Savings, Accuracy Gains, and Better Team Collaboration

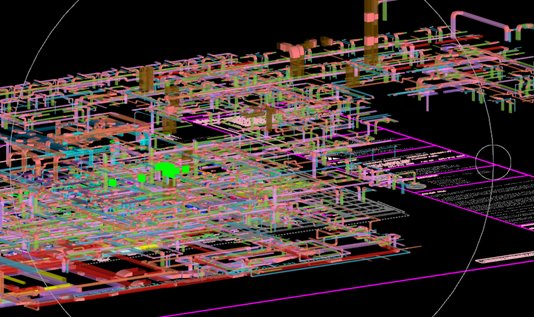

Figure 3. Full-floor ductwork layout without synchronized riser, modeled in Cubicost TME.

1. Significant Time Savings

The ability to isolate systems through colour filtering drastically reduced the time needed to identify and manage ducting works.

2. Reduced Errors

Layer prioritisation helped prevent system misidentification, reducing modelling and take-off errors significantly.

3. Improved Collaboration

With clearer, more organized 3D models, teams could communicate more effectively. Sharing and reviewing cost models across departments became seamless, improving overall coordination.

The implementation of Cubicost TME empowered Sunline to overcome project roadblocks and boost tender phase performance—setting a new standard for MEP digital workflows in Malaysia’s healthcare sector.

FAQs: Sunline M&E’s Glodon Cubicost TME Success at Avisena Specialist Hospital

What is Cubicost TME?

Cubicost TME is a digital quantity take-off solution designed specifically for MEP (Mechanical, Electrical, and Plumbing) works. It enables users to generate accurate cost models, identify systems easily, and manage large-scale 3D designs more efficiently.

Why did Sunline choose Cubicost TME?

Sunline selected Cubicost TME to overcome challenges related to overlapping 2D duct drawings and complex 3D models. The platform's Hide and Show by Colour and Layer Prioritisation features provided clarity, improved accuracy, and saved time during the tender phase of the Avisena Specialist Hospital project.

How does Cubicost TME help with project coordination?

By simplifying the process of identifying and managing MEP systems, Cubicost TME improves communication among teams. Clear, organized 3D models make it easier to share information, reduce misunderstandings, and avoid rework.

Can Cubicost TME be used for other types of buildings?

Absolutely. Cubicost TME is suitable for commercial, healthcare, industrial, and infrastructure projects. Its flexible tools can be applied across various building types to enhance MEP modeling, cost estimation, and project coordination.

Is Cubicost TME suitable for use during the tender phase?

Yes. In fact, many contractors adopt Cubicost TME during the tender phase to quickly and accurately perform quantity take-offs, improve decision-making, and increase their chances of winning bids through more efficient cost modeling.

Inspired by how Sunline M&E overcame complexity in hospital ducting systems? Your team can achieve similar success with the right tools. Glodon Cubicost TME helps simplify quantity take-offs, improve coordination, and bring structure to even the most detailed MEP models.

Whether you're working on healthcare, commercial, or industrial projects, Cubicost TME is built to reduce manual effort and deliver faster, more accurate results from the start.

Ready to take the next step?

Discover how Cubicost TME can enhance your project delivery. Get in touch with our team to begin your digital construction journey with Glodon Cubicost.