December 11.2025

Pine Grove Parcel B is a 56,264 m² residential development in Singapore designed for family-oriented living in a highly connected neighbourhood. To support early-stage cost planning and quantity measurement, King Wan Construction adopted Cubicost TME during the design and tender phases. By enabling faster drawing navigation, accurate system separation, and reduced repetitive measurement, TME helped the QS team respond efficiently to updates throughout the pre-construction process and prepare reliable cost estimates for this multi-unit residential project.

About the Project and King Wan Construction

Located near key schools such as Pei Tong Primary School, Henry Park Primary School, and the School of Science and Technology, Pine Grove Parcel B is designed to serve families seeking convenience and strong connectivity.

With a 38-month project duration and expected completion in 2028, the development required a robust digital approach to handle detailed measurements across multiple unit types and M&E systems.

King Wan Construction Pte Ltd, founded in 1977, is a Singapore-based integrated building services company specialising in Mechanical and Electrical (M&E) engineering. A subsidiary of King Wan Corporation Limited, the company provides multidisciplinary services including plumbing and sanitary, ACMV, electrical, fire protection, alarm systems, communications, and security systems, supported by decades of regional experience across Singapore, China, and Thailand.

Challenges in Multi-Unit and Multi-System Take-Off

During the quantity take-off process, several challenges emerged due to the scale and complexity of the residential development.

1. Multiple Residential Unit Types

Different residential unit types had to be measured and counted individually. The QS needed to manually go through each layout, identify the relevant quantities, and separate them by area, which required considerable time and attention to detail.

2. System-Based Classification for M&E Components

For mechanical and electrical (M&E) components such as water gate valves, the QS had to count each item by size and assign it to the correct system. For example, identifying gate valves on hot water pipes and classifying them under the hot water system.

3. Wide Range of Pipe Sizes, Materials, and Systems

The process became even more complex when dealing with a wide range of pipe sizes, materials, and systems. Each variation had to be recorded and summarized separately, with care taken to keep the breakdown neat and accurate.

4. Time-Consuming Cross-Checking

These repetitive and detail-heavy tasks made it difficult to speed up the workflow, especially when cross-checking across multiple drawings.

How Cubicost TME Addressed Key MEP Challenges

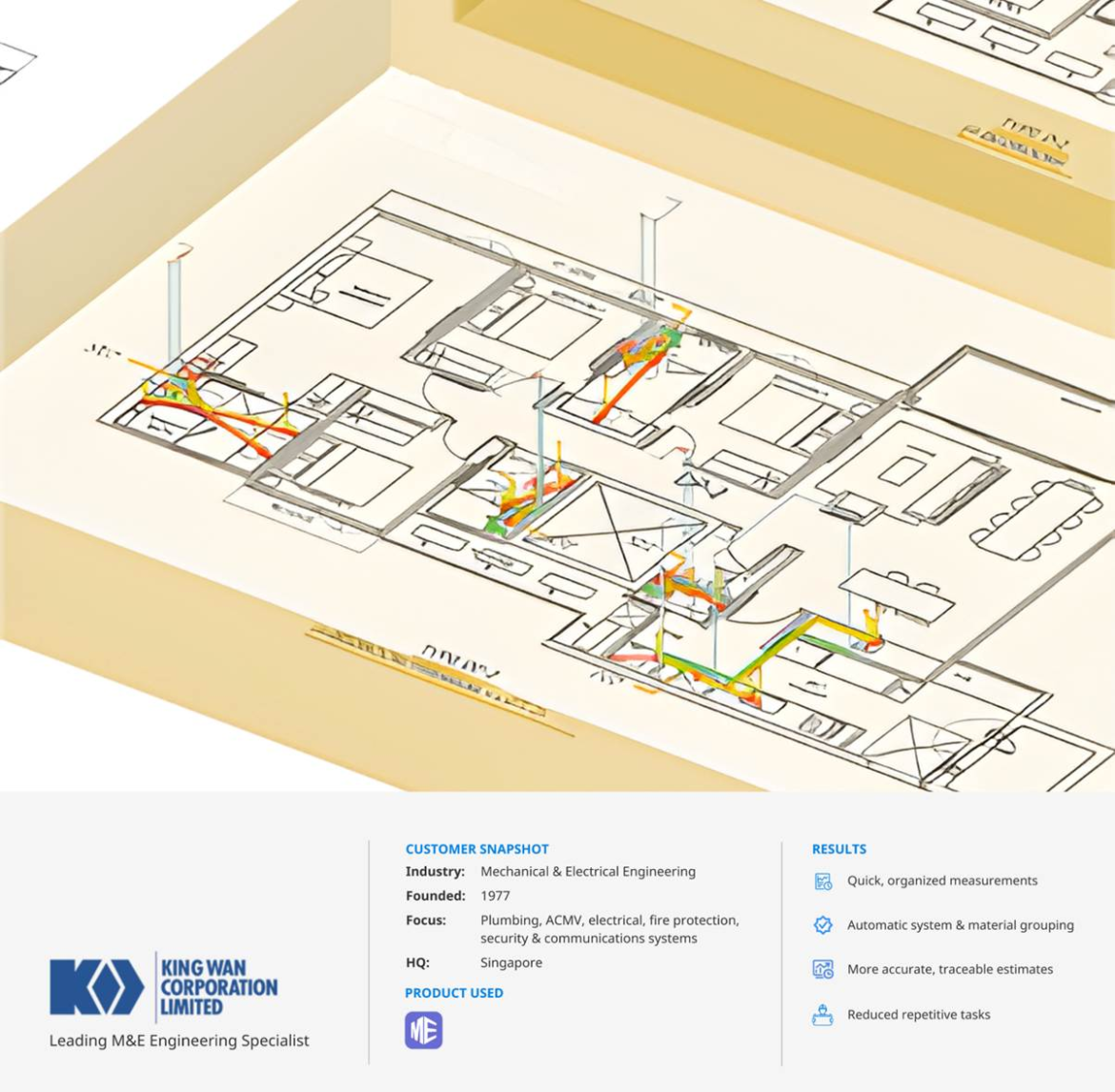

Figure 1. Plumbing and Sanitary System – Sanitary wares and piping works modeled using Cubicost TME

To address these challenges, Cubicost TME provides targeted functions that support clearer organization and more efficient quantity take-off.

1. Define Region for Unit and Area Separation

The Define Region function allows users to easily separate and manage quantities by specific zones such as by unit type or floor area. This significantly reduces the manual effort required to organize quantities.

2. Valve and Flange (P&S) Device Classification

The Valve and Flange (P&S) Device feature enables QSs to select valves of various sizes and systems, such as hot or cold water systems, where TME can automatically classify them accordingly.

3. Pipe (P&S) Single Line Definition

The Pipe (P&S) Single Line function allows users to input detailed descriptions of pipe size, material, and system, ensuring each item is clearly defined and properly grouped during measurement.

Together, these functions streamline quantity take-off, improve classification accuracy, and reduce confusion for M&E works.

Improved Efficiency During Pre- and Post-Contract Stages

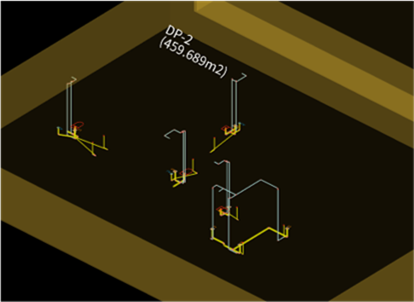

Figure 2. Plumbing and Sanitary System – TME visualised piping works routing including drop for easier checking and clarification

Leveraging TME’s capabilities, QSs were able to improve both efficiency and accuracy throughout the project lifecycle.

1. Reduced Repetitive Manual Work

The software helped reduce repetitive tasks and manual classification, allowing users to organize drawings, measurements, and material breakdowns more easily.

2. Clear System and Material Distinction

With functions such as Define Region, Pipe (P&S) Single Line, and Valve and Flange Device, users could automate classification and clearly distinguish between different systems or materials.

3. Better Traceability and Decision Support

This improved data traceability, reduced oversight, and enhanced confidence when preparing cost estimates. As a result, QSs were better equipped to support timely decision making and ensure consistency across project stages.

The Pine Grove Parcel B project demonstrates how Glodon Cubicost TME can significantly enhance MEP quantity take-off for complex residential developments. By enabling clearer system separation, automated classification, and accurate zone-based measurement, TME allowed King Wan Construction to streamline workflows, reduce manual repetition, and ensure reliable data traceability across pre- and post-contract stages.

Through improved clarity, faster verification, and better organisation of multi-system layouts, the QS team was able to support decision-making more confidently and keep pace with drawing updates throughout the design and tender stages. The result is a more efficient, structured, and transparent workflow that aligns with the demands of large-scale residential projects in Singapore.

If your team is looking to improve measurement accuracy, streamline classification, and strengthen coordination for MEP works, Glodon Cubicost TME can help you achieve the same level of digital precision.

To explore how TME can elevate your workflow, reach out to our team and start your digital transformation journey.