October 21.2025

As Southeast Asia’s demand for data storage and digital connectivity accelerates, the Johor Data Centre at Sedenak Tech Park (STeP) in Johor Darul Takzim stands as a critical milestone in Malaysia’s infrastructure modernization. Designed to deliver top-tier operational reliability, the 8,000 m² facility places strong emphasis on precision, safety, and compliance in its fire protection systems. To achieve this level of accuracy and efficiency, Globe Engineering adopted Glodon Cubicost TME, leveraging its digital modeling and automated quantity take-off capabilities to enhance coordination, reduce manual errors, and streamline project cost management during the tender phase.

About Globe Engineering and the Johor Data Centre Project

Globe Engineering Sdn Bhd, established on 27 August 1985, is a Malaysian-based specialist contractor in fire protection systems. Under the leadership of CEO Dame Wendy Tan, the company has built a strong reputation for providing end-to-end services in the design, installation, maintenance, and upgrading of fire protection systems. Globe Engineering is also known for its support in assisting clients with obtaining fire certificates for compliance and safety assurance.

With decades of experience, the company is committed to delivering reliable, compliant, and efficient fire safety solutions, backed by a team of Qualified Persons, licensed engineers, and fire safety experts. Globe Engineering’s mission is to be a leading specialist contractor in the firefighting industry, maintaining world-class standards of quality and customer satisfaction.

The Johor Data Centre project, located in Sedenak Tech Park (STeP), serves as a critical part of Malaysia’s high-tech infrastructure network. With an estimated completion in January 2026 and a 7-month duration, the project demanded exceptional precision in designing and installing advanced fire suppression and sprinkler systems. To manage the project’s complexity, Globe Engineering adopted Glodon Cubicost TME during the tender phase to achieve digital accuracy, transparency, and efficiency in cost planning.

Complex Challenges in Fire Protection Design and Cost Management

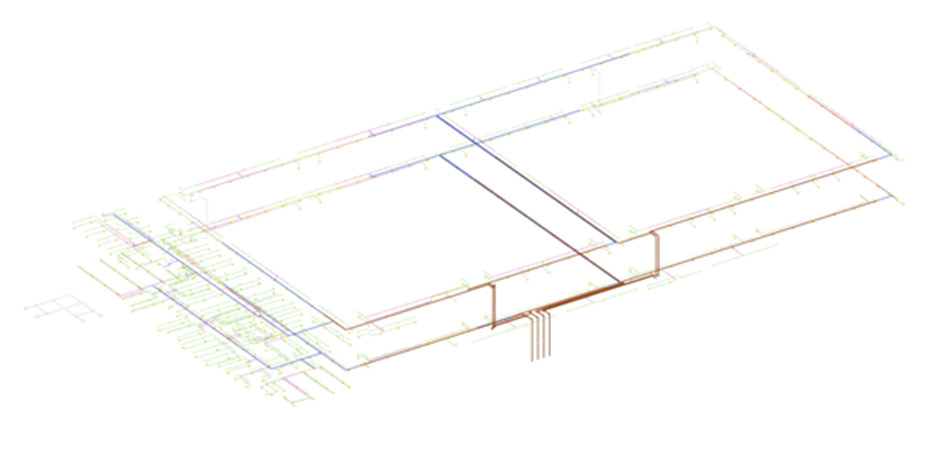

Figure 1. Piping Works of Multi-Disciplines on Cubicost TME

Before implementing Glodon Cubicost TME, Globe Engineering faced several key challenges that affected cost accuracy and coordination.

1. IG541 Gas Suppression System Design

The IG541 Gas Suppression System is designed with three layers of nozzles, include above the ceiling, below the ceiling, and below the raised floor. On-site, numerous offsets are required to avoid clashes with other building elements, and these pipe offsets must be counted accurately to prevent undercosting.

2. Pipe Quantity Separation and Categorization

The sprinkler pipes are served by four Pre-Action Valves across four distinct areas in the floor plan. While the total pipe quantity is essential for overall costing, separating the quantities for each valve is crucial to determine the Nitrogen Generator capacity.

3. Manual Take-Off from Incomplete Drawings

The piping for the IG541 Gas Suppression System requires manual take-off due to the absence of pipe sizes in the drawings. While oversight of information like this is a common occurrence, it does not diminish its inherent importance or relevance.

These challenges create a ripple effect, increasing the risk of errors, extending project timelines, and hindering collaboration among teams.

How Glodon Cubicost TME Enhanced Globe Engineering’s Workflow

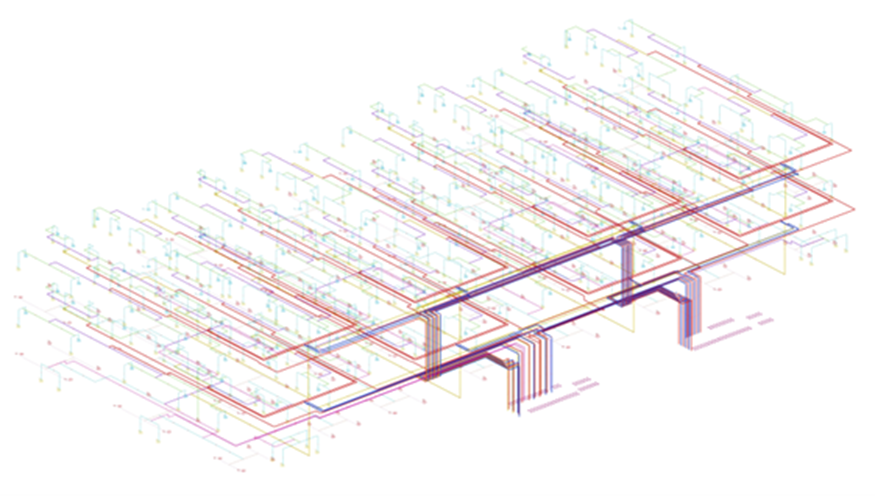

Figure 2. Piping Works of IG541 Gas Suppression System

To overcome these challenges, Globe Engineering adopted Glodon Cubicost TME, which offers advanced functionalities that significantly improved their workflow. Key features included:

1. Break and Adjust Elevation, Raise and Drop

These features enable users to adjust the elevation and obtain the extra pipe quantity due to the offset, ensuring accurate accounting for on-site modifications and reducing the likelihood of cost underestimations.

2. Define Region

This function enables users to easily separate the pipe quantity after overall quantity taking off, allowing for precise segmentation of data needed for components like the valve for determine the Nitrogen Generator capacity.

3. Single Line

This simple feature allows users to create and model all the pipelines efficiently, streamlining the take-off process even when drawings lack detailed specifications.

By integrating Glodon Cubicost TME into their workflow, Globe Engineering was able to manage complex designs more intuitively and efficiently. Modeling solution facilitated quicker iterations, better clash detection, and enhanced data accuracy during the tender phase.

Outcomes and Benefits of Glodon Cubicost TME

The adoption of Cubicost TME software brought significant improvements to Globe Engineering’s operations, addressing the core challenges and enhancing overall performance. Amongst the key benefits gain from the usage included:

1. Error Reduction

By automating quantity take-off and elevation adjustments, the software minimized errors in pipe offset calculations, leading to more reliable cost estimates and reduced undercosting risks.

2. Improved Accuracy and Separation

The ability to separate pipe quantities by region ensured precise determinations for Nitrogen Generator capacities while taking off overall pipe quantity, fostering better resource planning.

Inspired by how Globe Engineering enhanced precision and coordination for critical fire protection systems using Glodon Cubicost TME? Your team can achieve the same level of accuracy, efficiency, and control by adopting digital construction tools tailored for MEP works.

Whether your projects involve data centres, industrial facilities, or high-rise developments, Glodon Cubicost TME is built to simplify complex MEP quantity take-offs, improve collaboration, and deliver faster, more accurate results.

Ready to start your digital transformation?

Discover how Glodon Cubicost TME can help your team build smarter, safer, and more efficiently. Get in touch with our team today to begin your digital construction journey.