November 11.2025

In the heart of Singapore’s city centre, PDG SG3 Kappa stands as an ACMV-focused industrial project with a gross floor area of approximately 9,000 m². The project’s tender phase began in 2025, with construction scheduled to commence in 2026 and continue over a 12-month period.

To support the quantity take-off process during tender preparation, the client adopted Glodon Cubicost TME. By using TME, the quantity surveyor (QS) team efficiently extracted quantities with results that were clearly tabulated and easy to trace.

The software’s model-based environment enabled the team to double-check measurements after modeling, reducing errors before submission. Drawing comparison features also supported the identification of changes between revisions, allowing the QS to verify what elements had been added or removed. This level of clarity and traceability proved particularly helpful during tendering, ensuring accurate quantities and smooth coordination under tight timelines.

About Accesstech Engineering and the PDG SG3 Kappa Project

Accesstech Engineering (ACT), established in 1998, is a Singapore-based engineering and construction company known for its expertise in high-tech industrial manufacturing plants and data centres. As a top-tier and rapidly growing group, ACT delivers customised engineering solutions through a team of experienced professionals dedicated to precision and quality.

Operating with all departments under one roof, ACT ensures consistent quality and seamless project execution from contract confirmation to delivery. With a regional presence in Malaysia and Indonesia, ACT is strategically positioned to collaborate with multinational corporations across Southeast Asia. The PDG SG3 Kappa project further strengthens ACT’s reputation for innovation, efficiency, and excellence in data centre development.

Challenges in Segregating and Tracing Quantities by System

As the QS team handled multiple ACMV systems within a single drawing such as chilled water, hot water, and ducting, they encountered difficulties in identifying the correct routing and classification for each one.

1. Complex Multi-System Drawings

When several systems are shown in one drawing, it becomes challenging to isolate and trace the correct system paths accurately.

2. Manual Segregation Effort

The QS needed to manually separate, trace, and verify each system’s routing to ensure measurement accuracy.

3. Time and Coordination Burden

Without visual filters or automated classification tools, summarising and checking take-off results required significant time, adding complexity to coordination.

These challenges highlighted the need for a software solution that could visually segregate and manage multiple systems efficiently, enabling clear measurement and traceability.

Solutions Provided by Cubicost TME

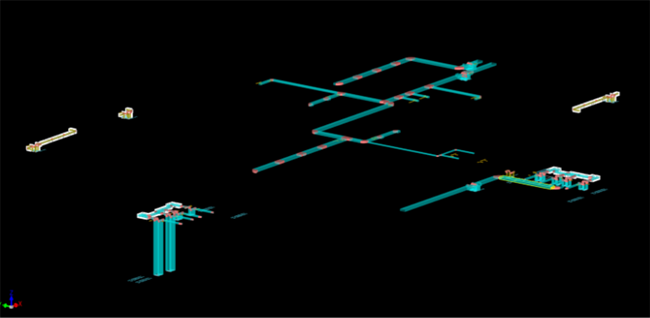

Figure 1. ACMV System – 3D View of Ducting Works

To address these challenges, Cubicost TME introduced several integrated tools that streamlined the measurement and coordination process.

1. Identify & Draw Features

These functions helped QS teams efficiently trace system components such as chilled water or ducting within a single drawing.

2. Structured Quantity Compilation

The Quantity function automatically compiled measurements into a clear, structured format, improving organisation and traceability.

3. Attribute and Layer Management Tools

The Attribute tool allowed tagging elements with details like pipe size or material, while the Layer Manager made it easy to isolate or hide systems, helping QS focus on specific scopes.

4. Enhanced Visualization and Control

With View controls, users could filter and display only selected components, reducing confusion when working with overlapping systems.

Advantages of TME Software

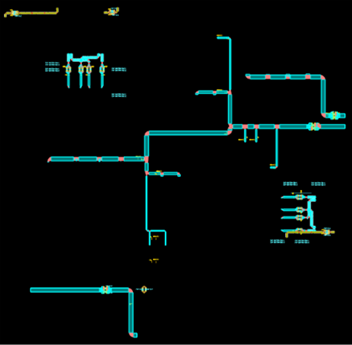

Figure 2. ACMV System – Ducting Works

Cubicost TME enhances the accuracy and efficiency of quantity take-off for mechanical and electrical (M&E) systems.

1. Quick Measurement and Identification: QS can easily obtain pipe measurements and distinguish systems using color coding for faster recognition.

2. Organized Data Management: The software allows summary generation by category, and the inclusion of detailed system-linked data.

3. Flexible Visualization: Layers can be hidden or shown as needed to reduce visual clutter, and 3D routing views help verify completeness and detect overlaps.

This improves traceability and stakeholder understanding, ensuring accurate and transparent results throughout the tendering process.

The PDG SG3 Kappa project demonstrates how Glodon Cubicost TME can transform the M&E quantity take-off process by providing clarity, automation, and accuracy in complex system environments.

By adopting TME, Accesstech Engineering successfully enhanced coordination, improved measurement precision, and reduced manual effort, while ensuring consistency and traceability under tight tender schedules.

Inspired by how Accesstech Engineering streamlined its quantity take-off process? Contact us today to explore how Cubicost TME can help your team achieve greater precision and efficiency in M&E projects.