December 05.2025

As Indonesia builds its new capital, Nusantara (IKN), one of its most symbolic structures is rising: the State Palace and Ceremonial Field. Covering more than 54,000 m² and constructed under an accelerated 26-month timeline, the project demands extraordinary accuracy, speed, and collaboration. To meet these demands, PT PP (Persero) Tbk implemented Glodon Cubicost TAS and TRB, transforming quantity take-off, reinforcement planning, and progress verification into a digital-first workflow.

About PT PP and the State Palace Project

The State Palace spans 35,938 m², supported by the 18,362 m² Ceremonial Field (Lapangan Upacara), designed to host major national ceremonies, including Independence Day celebrations.

Construction began on November 7, 2022 and is targeted for completion on December 25, 2024. As the main contractor, PT PP is supported by BIM engineers S Marcel Adiwinata and Sani Nur Fauzi, who adopted Glodon Cubicost during the construction phase to strengthen precision and efficiency for this national landmark.

Challenges in Delivering a National Landmark

1. Inefficient Manual Quantity Take-Off (QTO)

Polygon-by-polygon manual calculations slowed progress and introduced frequent errors, requiring repeated verification cycles.

2. Complex Reinforcement and Bar Bending Schedules (BBS)

Preparing BBS manually was time-consuming and prone to mismatches between planned requirements and on-site work, causing material waste.

3. Limited Accuracy in Field Progress Tracking

Manual methods hindered accurate volume checking, making early problem detection difficult and affecting decision-making quality.

4. Frequent Disputes Due to Poor Documentation

Without clear traceability, changes in material specifications or quantities caused disagreements and reduced stakeholder trust.

“As this project carries national significance, we could not afford the inefficiencies of manual methods. We needed a solution that could bring accuracy, speed, and transparency to every aspect of construction.”

— Fajrin Hernata, Site Engineering Manager, PT PP

Transformation with Cubicost: A Digital Leap in Construction

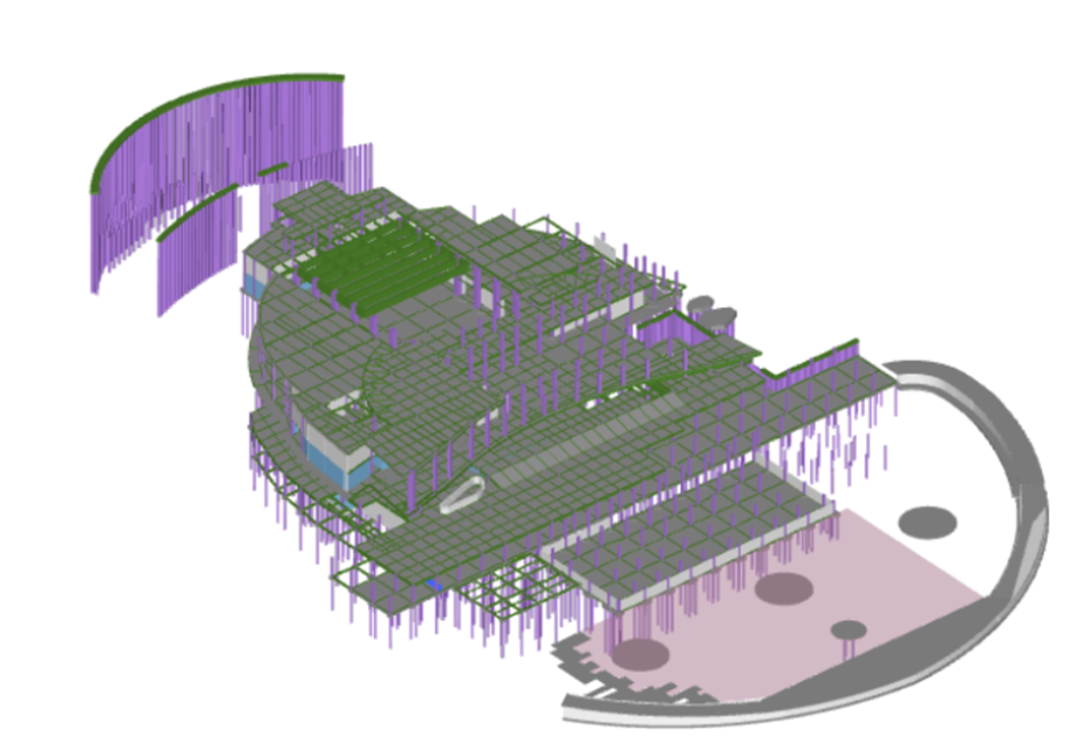

Figure 1. TAS Model of State Palace and Ceremonial Field

Glodon Cubicost TAS and TRB enabled PT PP to address the project’s complexities with greater confidence and control.

1. Reuse of Upstream BIM Models

By importing Revit models directly into Cubicost TAS, QTO that once required days could be completed far more efficiently, with automated measurement rules ensuring alignment with the design.

2. Accurate Bar Bending Schedules with TRB

The BBS feature in Cubicost TRB provided precise rebar cutting details, reducing mismatches and significantly lowering material waste during reinforcement production.

3. Segmentation for Progress Claims

Construction zones and segmentation functions enabled precise progress tracking and more reliable work verification.

“Cubicost gave us the ability to align design, quantity, and cost in one connected environment. It has changed the way we collaborate across teams and with stakeholders.”

— Lazuardi Fa, BIM Coordinator, PT PP

Results: Accuracy, Efficiency, and Stronger Collaboration

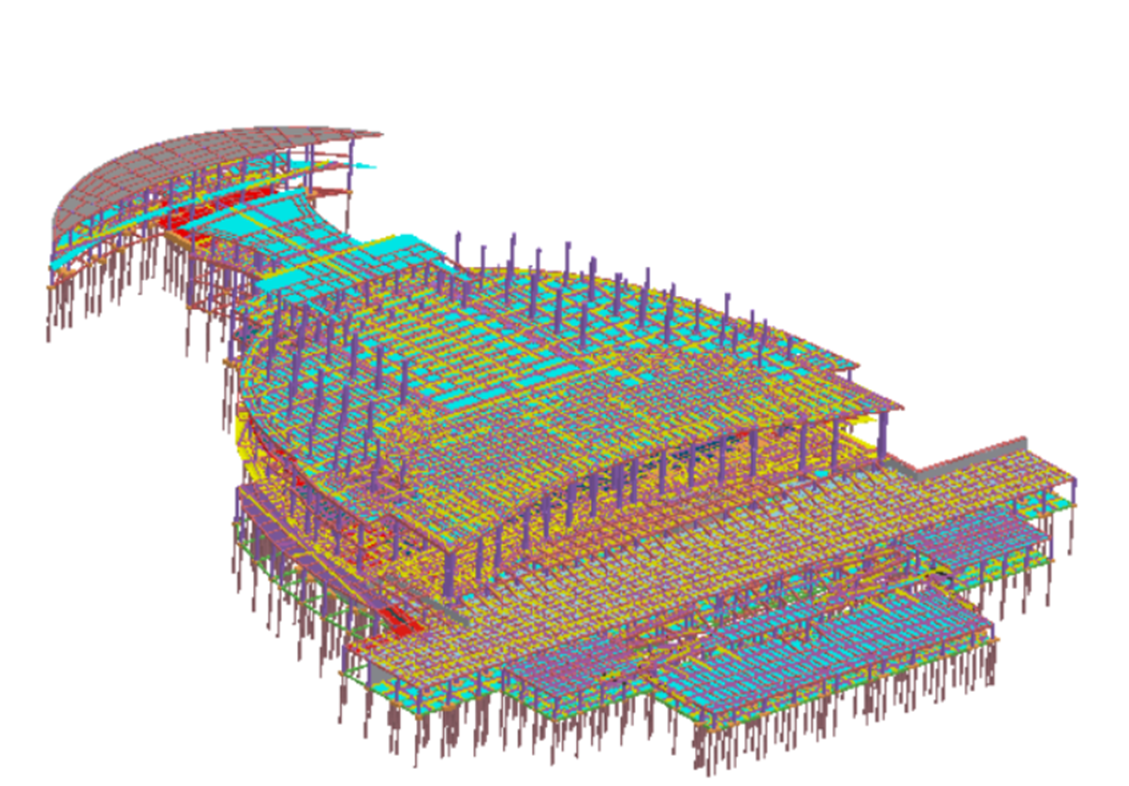

Figure 2. TRB Model of State Palace and Ceremonial Field

1. Clearer and more accurate Bills of Quantities (BQ) thanks to precise digital measurement.

2. Faster reinforcement detailing with TRB reducing BBS preparation from weeks to days.

3. Improved volume checking process, as field updates could be directly integrated into the model.

4. More transparent documentation, reducing disputes and improving stakeholder communication.

5. Lower risk of rework, with better early detection of design and quantity issues.

Cubicost empowered PT PP to deliver with greater reliability, speed, and data-driven confidence.

Building a Legacy for Indonesia

Figure 3. Personnel Skills Development with Glodon

For PT PP, the State Palace and Ceremonial Field are more than construction projects; they are national symbols that will define Indonesia’s future capital. By adopting digital tools like Cubicost TAS and TRB, PT PP is demonstrating leadership in modern construction practices, national development, and innovation.

“On a project of this magnitude, Cubicost is not just a tool — it is a necessity. It has given us the precision and reliability required to deliver one of Indonesia’s most important national landmarks.”

— Bagus Maulana, BIM Engineer, PT PP

This project reflects PT PP’s commitment to excellence and showcases how technology can elevate the delivery of iconic infrastructure.

The State Palace and Ceremonial Field will stand as enduring proof of how digital construction drives national progress. With Cubicost TAS and TRB, PT PP has set a new benchmark for accuracy, transparency, and efficiency in Indonesia’s most important projects.

If your team is looking to strengthen construction accuracy and workflow efficiency, explore how Glodon Cubicost can transform your approach to quantity take-off and reinforcement management.