November 19.2025

A landmark is rising in Pantai Indah Kapuk 2 (PIK 2), where architectural ambition meets digital precision. The BNI Building, a striking 81,571 m² office complex designed with a diamond-shaped façade, represents one of Indonesia’s most distinctive high-rise developments. Combining a steel and concrete composite structure with both unitized and stick curtain wall systems, the project places heavy demands on coordination, accuracy, and material control.

Scheduled for completion between February 2024 and July 2025, the project spans seventeen months of intensive work led by PT Pembangunan Perumahan (Persero) Tbk, widely known as PT PP. Supported by BIM engineers S Marcel Adiwinata and Sani Nur Fauzi, the contractor leveraged Glodon Cubicost TAS and TRB during the tender and construction phases to enhance speed, accuracy, and transparency in quantity take-off and structural detailing.

About PT PP and the BNI Building Project

Located within the rapidly developing PIK 2 district, the BNI Building is designed as a modern architectural icon that merges unique geometry with structural rigidity. Its complex form places high demands on steel and reinforcement design, making precise calculations essential from the earliest stages of construction.

PT PP, established in 1953, is one of Indonesia’s leading state-owned construction enterprises. With expertise across building, civil infrastructure, EPC, plants, equipment, and property development, the company continues to push digital innovation in construction. Its adoption of Glodon Cubicost tools for the BNI Building showcases its commitment to leveraging advanced technologies for efficiency, accuracy, and improved project delivery outcomes.

Project Challenges in the BNI Building Construction at PIK 2

|

|

|

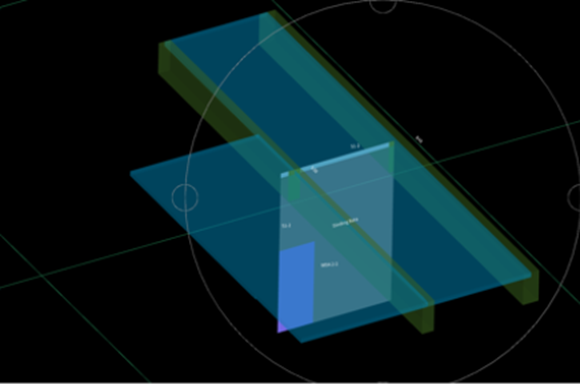

Figure 1. Cubicost TAS – 3D Deduction View showcasing automated volume deductions at structural intersections

Large-scale, high-rise projects come with several technical challenges, and the BNI Building was no exception. PT PP faced multiple complexities that demanded precise and timely solutions:

1. Extensive Steel Structural Components

The project required meticulous review of structural drawings to ensure that the large number of steel items were accurately represented in the Bills of Quantities. Missing or incorrect items could lead to major discrepancies in cost and material planning.

2. Inefficient Traditional Volume Calculation Processes

Conventional methods for calculating structural volumes were time-consuming. The process required long verification periods and carried a higher risk of inaccuracies, especially in flexible zones that needed to adapt to site conditions.

3. Complex Reinforcement and Structural Connections

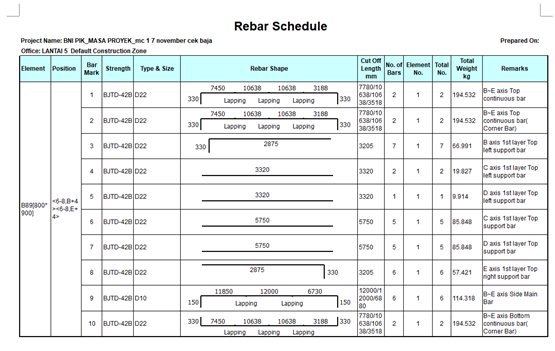

Multiple steel types and varying reinforcement schedules meant that preparing accurate Bar Bending Schedule (BBS) drawings required tremendous effort. Even minor miscalculations could lead to costly delays or rework in the construction sequence.

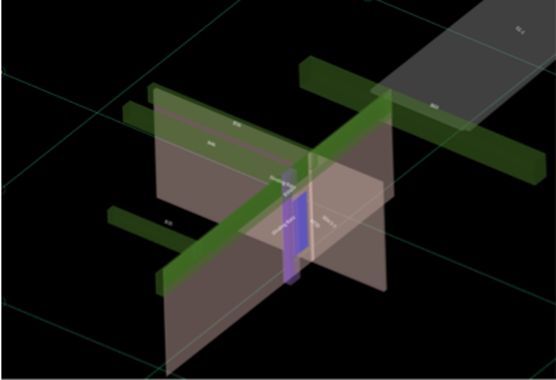

Figure 2. Beam Rebar Layout and Bar Bending Schedule produced using Cubicost TRB

How Glodon Cubicost Improved Accuracy and Speed

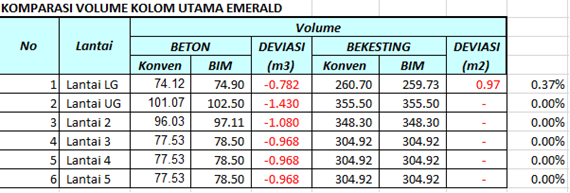

Figure 3. Manual Calculation vs Cubicost BIM-based Calculation for main column volume analysis

To overcome these challenges, PT PP utilized the integrated capabilities of Glodon Cubicost TAS and TRB, enabling faster, more reliable calculations and improved coordination across teams.

1. 3D Deduction View for Structural Intersections

Using Cubicost TAS, engineers visualized structural overlaps in 3D and automatically deducted intersecting material volumes. This ensured highly accurate calculations and better control over material usage.

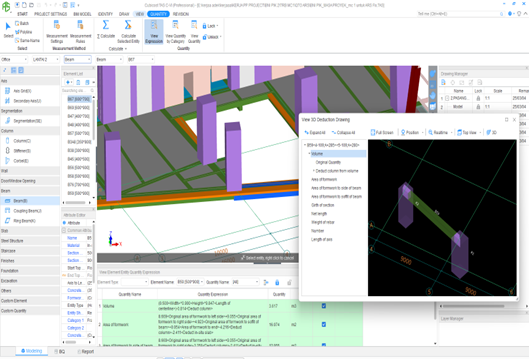

Figure 4. View Expression and 3D Deduction View within Cubicost showcasing transparent calculation formulas

2. Formula-Based Measurement Rules and Fast Revision Handling

Measurement rules allowed the team to set precise formulas for complex structural components. When design revisions occurred, Cubicost recalculated materials quickly, preventing delays in the workflow.

3. Major Efficiency Gains with the BBS Module

Cubicost TRB significantly reduced the time needed to prepare reinforcement drawings. Manual BBS work that previously required over six weeks could now be completed in less than one week, representing an 80 percent time saving.

4. Accelerated Structural Volume Calculations

Volume calculations that traditionally took more than eight weeks were completed in under two weeks using Cubicost, reducing time by approximately 75 percent.

5. BIM-Based Accuracy Validated Against Manual Take-Off

In analyzing the main columns of the Emerald Building, discrepancies between BIM-based and manual calculations ranged from zero to one percent, demonstrating the reliability of Cubicost’s automated results.

Results that Transformed Quantity Surveying Workflow

Figure 5. Rebar Schedule generated automatically using Cubicost TRB

By integrating Glodon Cubicost TAS and TRB into the BNI Building workflow, PT PP achieved improvements that extended far beyond basic calculation efficiency.

1. More Efficient Steel Volume Estimation

Enhanced accuracy and speed ensured that steel materials were planned and executed with reduced waste and stronger cost control.

2. Higher Precision for Architectural and Concrete Structure Calculations

Visual verification through 3D models improved confidence in take-off results and streamlined coordination among disciplines.

3. Full Transparency in Calculation Logic

The view expression feature displayed formulas used in each calculation, making it easier for stakeholders to verify and trust the data.

4. Fewer Drawing and BBS Errors

The software reduced errors commonly associated with manual BBS preparation, while recalculations for shop drawing changes were identified almost instantly.

5. Reliable Support for Volume Checking and Work Claims

Cubicost served as a dependable reference for validating material quantities and verifying progress claims throughout the project.

The BNI Building at PIK 2 exemplifies how digital solutions like Glodon Cubicost TAS and TRB can elevate accuracy, streamline calculations, and transform the workflow of large-scale construction projects. PT PP’s successful use of Cubicost demonstrates how technology enables better decision-making, faster processes, and stronger project coordination.

Inspired by how PT PP improved efficiency and precision with Glodon Cubicost? Contact us today to explore how Cubicost can enhance your project delivery from tender to construction.