November 26.2025

A new mixed-use neighbourhood centre is taking shape in Sengkang, Singapore, covering approximately 28,000 m² of gross floor area. Designed to integrate a 15-storey residential tower with commercial school facilities, retail spaces, and multi-storey carparks, the development aims to address evolving urban lifestyle needs in the heartland.

To support accurate cost estimation and project measurement, the client adopted Cubicost TME during both the tender and construction phases. With tight timelines, frequent drawing revisions, and the need for rapid approvals, the project team relied on TME to ensure quantity accuracy, maintain traceability, and streamline communication without inflating overall project costs.

About K.B.C. Engineering and the Sengkang Neighbourhood Centre Project

The Sengkang neighbourhood centre represents Singapore’s continued push for well-integrated community spaces. For K.B.C. Engineering, accurate measurement of fire protection systems, piping layouts, and related M&E scopes was critical to supporting tender submissions, progress claims, and variation order (VO) discussions.

Established in 2008, K.B.C. Engineering is a Singapore-based specialist contractor providing design, supply, installation, and maintenance of fire protection systems for diverse building types. With more than a decade of experience and strong familiarity with Singapore’s strict fire safety regulations, the company delivers reliable, compliant, and high-quality fire protection solutions across commercial and residential developments. By integrating Cubicost TME into this project, K.B.C. enhanced its ability to manage quantities efficiently and support transparent communication among stakeholders.

Challenges in Quantity Traceability and Fast-Paced Construction Requirements

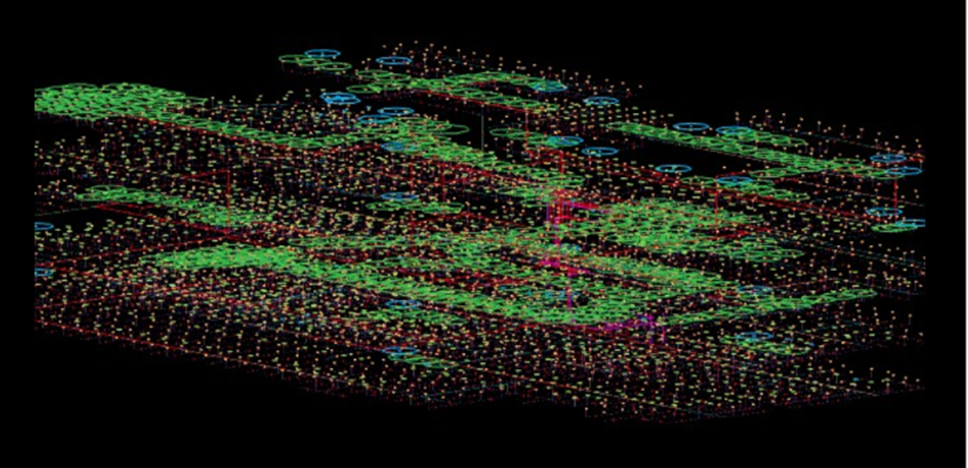

Figure 1. Fire Protection System – Sprinkler and Piping Model Created Using Cubicost TME

During both the tender and construction phases, the project team encountered several key challenges that made traditional quantity take-off methods difficult:

1. Untraceable Quantities and Limited Visual Validation

One of the most significant issues was the inability to trace measured quantities accurately back to their specific locations on the drawing. Without clear visualisation, it was difficult to understand design changes or validate quantities during stakeholder discussions.

2. Frequent Claims and VO Discussions

Progress claims and variation orders were common, which meant quantities had to be verifiable and easy to present. Without a proper model, resolving measurement-related disputes became time-consuming and inefficient.

3. Manual Mark-ups and Inconsistent Accuracy

In the construction phase, mark-ups were often done on printed drawings or photos. This made it almost impossible to automatically generate quantities or maintain consistency, leading to inefficiencies and higher risk of inaccuracies.

4. Tight Timelines for Take-offs

The team worked under significant time constraints, requiring take-offs to be fast, accurate, and aligned with the latest drawing changes. Manual workflows could not keep up with the speed required.

How Cubicost TME Addressed Quantity Accuracy and Traceability

Figure 2. Fire Protection System – Sprinkler and Piping Layout Generated with Cubicost TME

To overcome these challenges, the project team leveraged several key features of Cubicost TME:

1. Identify and Draw / Auto Identify by Level

Enabled the team to efficiently generate quantities from complex drawings across multiple levels, reducing time spent tracing routing manually.

2. Adjustable Brightness for Clearer Verification

Improved visibility by helping users distinguish model elements from 2D drawings, supporting faster and more accurate verification.

3. Hide and Show Commands for Detecting Drawing Changes

Allowed users to isolate specific entities, identify duplicated elements, and spot changes quickly, ensuring consistent quantity accuracy.

4. Layer Manager for Focused Measurement

Helped filter out unnecessary drawing elements, enabling users to focus only on relevant components and maintain higher precision in take-offs.

TME's Impact on Quantity Management and Dispute Resolution

Cubicost TME significantly improved how the project team handled quantity-related tasks throughout tendering and construction. With model-based visibility and fully traceable quantities, disagreements during progress claim or VO discussions were resolved more quickly and with greater confidence.

Stakeholders could clearly visualise design changes and understand how quantities were generated, which reduced delays and sped up approval processes. The reduction in manual checking meant the team could spend more time on higher-value activities such as design compliance, cost analysis, and risk assessment.

Compared to traditional workflows, quantity take-offs were completed in much less time, and the overall process became more organised, accurate, and transparent. Beyond improving accuracy, TME strengthened trust among stakeholders by providing a shared visual reference that everyone could rely on.

The Sengkang Neighbourhood Centre project demonstrates how Cubicost TME can support both tender and construction workflows by enhancing accuracy, speeding up take-offs, and reducing disputes through traceable, model-based measurement.

By adopting TME, K.B.C. Engineering successfully improved coordination, accelerated quantity verification, and ensured clarity in progress claim discussions. This modern approach to MEP and fire protection quantity management marks a significant step in the company’s ongoing commitment to precision, compliance, and digital excellence.

If you would like to explore how Cubicost TME can help your team achieve the same level of accuracy and efficiency, contact us today to learn more.