October 02.2025

Introduction

Every construction project begins with numbers. Budgets, schedules, and quantities are the foundation of successful delivery. Among the most important of these numbers are the quantities of reinforcement steel (rebar), the backbone of modern reinforced concrete structures.

Getting those numbers wrong, even slightly, can ripple across the entire project. Inaccurate rebar estimation often results in wasted material, cost overruns, and delays that undermine profitability and trust. Conversely, accurate rebar takeoff, the process of determining exact steel requirements, creates efficiency, certainty, and competitive advantage.

To illustrate the stakes, consider this: on a 10,000-square-meter residential project, a 5 percent error in rebar estimation could mean 50 tons of unnecessary steel. At current market rates, this is not just a budget issue, it is a serious financial setback that could impact cash flow, procurement schedules, and even the viability of the project itself.

This article explores why rebar takeoff is so challenging, how inaccuracies affect project outcomes, and how modern approaches can transform the process into a source of cost and time savings.

What Is Rebar Takeoff?

Rebar takeoff refers to the calculation of how much reinforcing steel a project requires, based on structural drawings and specifications. It includes not only straight quantities but also bar sizes, lengths, bends, hooks, overlaps, and deductions for intersections.

Traditionally, takeoffs are done manually using 2D drawings and spreadsheets. For small, simple projects, this might be manageable. But on larger, complex structures with extensive reinforcement, manual methods quickly become error-prone and time-consuming.

Why Accuracy in Rebar Takeoff Matters

1. Cost Control

Steel is one of the most expensive materials in concrete construction. Even a 5 to 10 percent miscalculation can mean tons of unnecessary rebar, inflating procurement costs. On the flip side, underestimation forces emergency orders that often come at higher prices and disrupt schedules.

2. Time Efficiency

Manual estimation requires meticulous counting and rechecking. A single design change can trigger hours of recalculation. Projects working on tight deadlines cannot afford such inefficiency.

3. Reduced Waste

Overordering does not just hurt budgets, it also creates storage issues and scrap. By matching rebar quantities precisely to structural needs, contractors reduce waste and support more sustainable construction practices.

4. Better Planning

Reliable rebar data helps procurement teams schedule deliveries, contractors plan labor, and managers control risk. Inaccurate numbers throw all of these downstream activities off balance.

The Challenges of Manual Estimation

Despite best efforts, traditional workflows make it difficult to achieve precision in rebar takeoff. Common pain points include:

1. Interpretation differences: Structural drawings may be ambiguous. Different estimators can arrive at different results.

2. Design changes: A modified beam depth or bar spacing often means recalculating large portions of the takeoff.

3. Overlaps and deductions: Manual methods struggle to consistently account for overlaps between structural elements.

4. No visual confirmation: Without a 3D model, it is hard to verify whether bars are being double-counted or missed.

5. Weak traceability: If challenged on the numbers, estimators often lack a clear audit trail of how quantities were derived.

These issues compound quickly. Studies suggest that manual estimation errors can range from 5 to 15 percent. On large-scale projects, that margin can mean serious financial losses and strained client relationships.

Smarter Rebar Takeoff with Technology

To address these challenges, the industry is increasingly turning to software designed specifically for rebar estimation. These tools replace guesswork and spreadsheets with model-based logic, automation, and traceability.

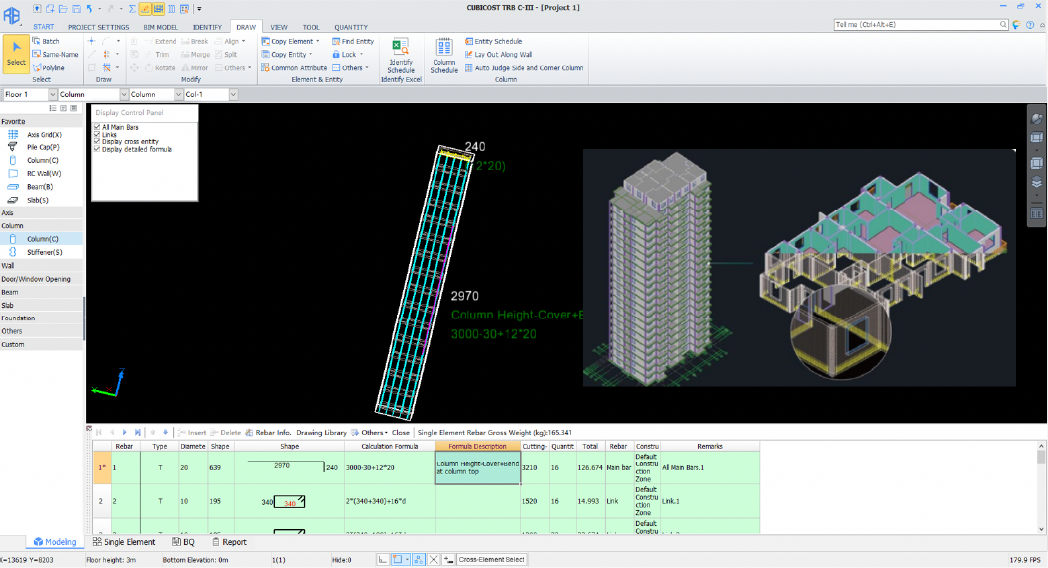

One example is Glodon Cubicost, a solution purpose-built for rebar takeoff. Rather than selling steel or construction services, Glodon Cubicost provides a more reliable way to handle quantities by linking design, geometry, and rules in a digital model.

Key Features of Modern Digital Rebar Takeoff Tools

1. Quick modeling: Import DWG or PDF drawings and convert them into a digital model for takeoff.

2. Automated quantity extraction: Built-in rules apply deductions and overlaps consistently, reducing errors.

3. Instant updates on design changes: When drawings are revised, the model recalculates quantities automatically.

4. 3D visualization: Engineers and contractors can see exactly how rebar is placed, providing clarity and reducing disputes.

5. Flexible reporting: Outputs such as bar bending schedules (BBS) and Excel sheets make data easy to share and integrate.

These features help transform estimation from a vulnerable manual task into a controlled, transparent process.

Real-World Gains

The benefits of smarter rebar estimation are not theoretical. They are being realized by contractors worldwide.

1. Material savings: Firms report 5 to 15 percent reductions in reinforcement costs due to more precise orders.

2. Time efficiency: Automated takeoffs and instant updates reduce workflows that once took days to mere hours.

3. Clearer collaboration: With visual models and traceable logic, engineers, contractors, and QS teams can align more easily.

4. Defensible estimates: Every number can be linked back to a model element, reducing disputes and making audits straightforward.

For example, developers in Southeast Asia have used Glodon Cubicost to cut estimation time by more than half. Contractors in the Middle East have applied it to streamline collaboration on large, complex projects. Smaller builders also report benefits: even on modest residential jobs, reliable rebar takeoff helps avoid last-minute material shortages that frustrate both clients and crews.

These outcomes show how accurate rebar takeoff directly translates to cost certainty and smoother execution.

The Bigger Picture: Efficiency and Sustainability

Accurate rebar estimation is not just about cutting costs. It also supports broader industry goals.

1. Lean construction principles: Reducing waste and focusing resources where they are needed most.

2. Sustainability goals: Less steel waste means lower embodied carbon and more efficient use of materials. For contractors pursuing green building certifications, this accuracy strengthens environmental credentials.

3. Smarter procurement: With better forecasting, procurement teams can negotiate more favorable contracts and reduce reliance on emergency orders.

4. Stronger client relationships: Reliable numbers build trust with owners and stakeholders, helping contractors win repeat business and strengthen reputation.

In an industry where margins are tight and deadlines unforgiving, the shift from manual estimation to digital takeoff is more than an upgrade. It is a necessity that supports both business and sustainability objectives.

Conclusion

Rebar takeoff may appear to be just another line item in preconstruction, but in reality, it sets the tone for cost, efficiency, and project success. Inaccurate estimation creates hidden waste, weakens profitability, and fuels disputes. Accurate estimation, by contrast, delivers clarity, savings, and confidence.

If you’re ready to make rebar estimation more accurate, minimize material waste, and deliver projects with greater confidence, discover how Glodon Cubicost can transform your next construction takeoff. Book a free demo of Glodon Cubicost to see how accurate rebar takeoff saves time and cost on your next project.