Design ventilation systems with the exact components, sizes, connections as the final installation.

- Use male/female fitting types to avoid unnecessary joints

- Change ducts to joints with the correct length

- Lock product choices before final sizing

- Automatically check that the system is buildable

Design accuracy is essential because of its benefits on everything from production to coordination to installation. Greater accuracy enables efficient material listings, is vital for interdisciplinary coordination, and assists installation tasks.

When you want to make a production model (i.e. a model that enables an exact component listing) of your ventilation design, the model needs to have the same fittings, size selections and connections as the final installation. MagiCAD includes several features that enable precise and accurate production model design.

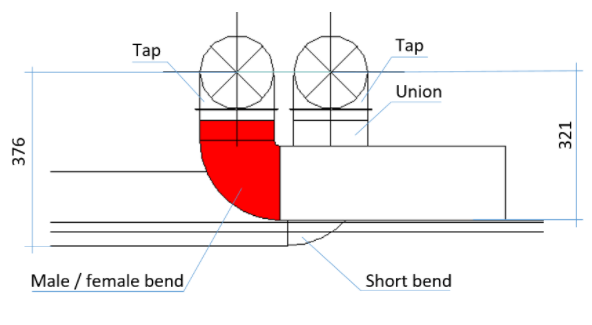

Normally two standard fittings cannot be connected directly, as all connectors are male connectors, and a space-taking joint is needed in between. The possibility to distinguish between male and female connectors eliminates the need for additional joints and allows for a variety of new design configurations.

Changing a duct between two fittings to a joint with the correct length is easy with the Duct-to-union feature. The new joint is included in bill of materials lists and the connected ducts are automatically placed correctly.

When using male/female fittings, the rotation of the fitting can be easily corrected if needed with a Swap connection feature so that the male/female connectors are in the right place.

To help with product selections, the Smart product lock function allows you to lock the product choice but keep the product size editable. This allows you to make product selections already before the system and product sizing has been finalized.

MagiCAD also helps designers ensure that their design is buildable. When you size a duct system or update it with Production Model Updater, an automatic consistency control checks the system and lists any issues in BCF Manager for review.

MagiCAD helps you design a ventilation system exactly as it will be built.